The sugar cane machines do not have a very complicated construction, and most of them have very similar designs. Most of these machines are manufactured in China, but some in India, Vietnam, the Philippines, and other countries. Thus, there is a common problem with the goods produced in China. They are made by unknown local companies and distributed by many small distributors, often short-lived and under a large number of different names.

There are two major types of dedicated sugar cane juicers available on the market – the Manual or Mechanical and Electric or Motorized – and both are designed to do a decent job extracting sugar cane juice.

These sugar cane machines are commercial type, and the major problem with the commercial sugar cane dedicated machine is their price tag; most of them usually cost more than $1000. However, you can still find decent dedicated sugar cane machines for an affordable price, and this article will help you do it.

Disclosure: As an Amazon Associate, we may earn an affiliate commission for purchases you make when using the links on this page.

Table of Contents

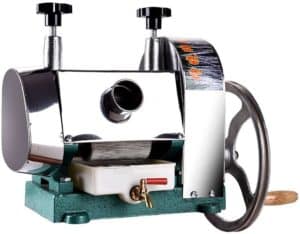

Manual Sugar Cane Juicer Press

The sugar cane manual machines are very efficient and squeeze to the last drop. They are cranked by hand by rotating the handle connected to the wheel on the side of the machine.

The user feeds the sugar canes shute into the feeding throat of the machine. The feeding process may require some effort from the user to push the cane into the throat. The machine rollers press the cane shoot, and the dry fiber is ejected via an ejection notch while the juice passes through the juice outlet. The mechanical sugar cane juicer is designed to process about 50kg of juice in an hour.

INTSUPERMAI/SmarketBuy Manual Sugarcane Juicer Press

Parts: The INTSUPERMAI Manual Sugarcane Juicer Press and most other manual sugar cane machines are constructed with the following parts:

- Metal Body,

- Hand Wheel,

- Stainless steel tray with filter,

- Juice outlet,

- Feed inlet,

- Cinder notch (pulp ejector),

- 3 rollers/gears,

- Pressure adjusting knobs.

Machine Body: The machine’s gears/rollers and removable shell are made of food-grade 304 stainless steel due to exposure to high-pressure exposure. The base and handle wheels are made of painted cast iron.

The roller’s construction comes with a gear reducer and shockproof features to ensure good torque and shockproof attributes.

Functionality:

- Sugar Cane,

- Ginger,

- Sorghum bar,

- Cornstalk.

Juicing container: The machine features a stainless steel tray with stainless steel filter and a juicing outlet with a tap. The filter strains the juices before they can be released with the juicing tap.

Feed inlet: The machine features a round feed inlet that fits a whole of up to 2″ thick sugar canes, while splitting them makes feeding easier. However, the canes under 1.18”/30mm in diameter are the best to feed; otherwise, they may cause overloading, and the machine may stop pressing and will require reverse action. So the canes larger than 1.12” in diameter are the best to break in half.

Cinder Notch/Pulp Ejector: The rear of the machine is equipped with a cinder notch, which ejects the flat and dries the cane stalks.

Gears/Rollers: The juicer comes with three (3) heavy-duty rollers, which are 4.25”/108mm long, 2.95”/75mm in diameter wide, and have 0.2” teeth. The roller’s core part is made of stainless steel to withstand high-stress exposure, while the coating is made of iron cast.

The Gears rotated with a slow 25 RPM speed and delivered the highest quality cold-pressed juice.

Many people argue that the rollers’ coating is not stainless steel tend; they are predisposed to rust. However, if you clean your machine immediately after use and dry it with a cloth, it will not be the case.

Using and Cleaning: The assembly is not difficult. It requires first sliding the wheel onto the shaft and the small key on the side of the machine body. And to tighten an adjustable spanner to the shaft nut. Then, attach the juicing tap to the juicing tray, and it is ready to operate.

The cane stalks do not need a lot of preparation before juicing them with a manual sugar cane machine. You do not need to cut or peel them off but have to wash and scrap them a little to remove mold and bugs.

The manual juicer machine works just by manually operating with a hand crank pulley on the wheel on the side of the body machine. This makes the rollers/gears move and squeeze out the juices from sugar cane stalks. If the machine stopped working due to the jamming, then reverse just swings directly.

And if you use the thinner canes, it is better to remove the metal covering as it restricts the stalk movements. The stalks must be fresh; otherwise, the yield will be low. A thicker canes machine will struggle for juicing, and you need to have them.

To keep your machine in good order and prevent rusting, pitting, or moisture build-up, spray it with food-grade silicon.

Dimensions: 14” X 14.5” x 9”, weighs 72 pounds.

Yield: One cane 5–6 feet long and 1–1.2” in diameter will make 1–1.5 cups of juice. If you pass each piece twice through the juicer, it will take up to 3 cups of juice.

Summary: These machines are great for extracting the sugar can juice, and they deliver a great yield, never mind it is a mechanical machine. The price is more than reasonable, and you can buy it for around $200, usually the Chinese version. However, you have to use muscles to hand-crank the machine. It is ok to do 1 to 5 stalks at a time; however, you better get the belt and the motor and make it motorized for more volume.

Electrical Sugar Cane Machine Juicer

Electric and Mechanical Sugar Cane machines have pretty similar construction. Though, an electrically Juicer extracts juice from the canes shoots the same way as mechanical ones.

The cane stalk is fed into the feeding hole, and it is almost self-fed because it does not require any muscle strength from the user. The sugar can stalk passed through the rollers (usually from 3 to 6 rollers), and the machine automatically discharges the pulp and juice.

The electrical sugar cane presses are designed to process approximately 280kg of cane shoots in one hour.

INTBUYING/Shiksha Electric Sugar Cane Juicer 110V Commercial Sugar Cane Ginger

You can also come across the same sugar cane machine design but marketed under the following names — VEVOR, VBENLEM, PROMOTOR, Techtongda Commercial Sugar Cane Juicer, INTBUYING Commercial Sugar Cane Juicer, and others.

Parts: This type of machine is usually constructed with the following parts:

- Metal Body,

- Stainless steel tray with strainer and juice outlet,

- Feed inlet,

- Cinder notch (pulp ejector),

- 3 rollers/gears,

- 2 roller pressure adjusters.

- User Manual

Machine Body: The sugarcane press extractor’s entire unit body is made of anti-corrosion and anti-rust stainless steel.

It is an in-house, 110 V, 370 Watts 100% copper motor that rotates the gears with a slow 25 rpm that allows 280 kg/h.

This juicer is designed for 1–2 hours of continuous operation before it should be stopped for rest.

This sugar cane machine features a feeding inlet, pulp outlet, and a place for inserting a juicing tray with a filter.

Functionality:

- Sugar Cane,

- Ginger,

- Sorghum,

- Cornstalk.

Juicing container: The juicer is equipped with a stainless steel container that comes with a stainless steel strainer to sieve the juicer from the excess pulp. The container also has an inbuilt juice outlet; this could open and close and release the juice whenever you decide to do it. The container slides inside the juicing body.

Feed inlet: The machine features a circle-shaped 1.97”/50mm sugar cane feeding inlet, which allows feeding the entire stalk without pre-cutting. The machine is also equipped with a reverse function, so if it’s a jam, you use it for an unclogging machine. However, it is not usually the case, especially if you cut the cane edge in a wedge shape.

Gears/Rollers: The machine is equipped with three (3) durable food-grade stainless steel gears/rollers. The cane shoot is pressed between these rollers for juice extraction.

Pressure Adjusters: The machine comes with two (2) pressure adjustment knobs, which are by pressing or releasing the four (4) internal springs that will adjust the rollers’ gaps. One clockwise turn will the rollers gap by 0.06″/1.5 mm to accommodate the thinner cane shoots, while the counter-clockwise turn will release the spring and increase the roller’s gap for fitting the thicker canes.

Using and Cleaning: The machine is self-feeding; you do not need any effort to feed the shoot. Just cut the cane end in wedges for easy feeding before fitting it into the machine feeding shaft.

Operation: The machine operates with three buttons with On, Off, and reverse functions. The reverse function will change the direction of the roller rotation if it jams.

Cleaning: this machine is easy to clean; hose off it with water to clean all the stickiness out of the machine, dry it with a cloth, and it is done.

Dimensions: 23.6” X 16.5” x 14.2”/60 X36 X42 cm, weighs 115 lbs/52 kg.

Yield: On average, the machine will press 2–4 cups of cane juice from 2–3 cane shoots.

Summary: It is very worth considering if you are looking for an electric sugar cane machine. It is the cheapest among the array of similar sugar cane juicers and comes with pressure adjustment knobs that efficiently process cane shoots of various sizes. There is no other way to buy a dedicated machine to do your sugar cane quickly and easily.

How to Choose Between Manual and Electrical Sugar Cane Press

Selecting between mechanical and electric sugar cane machines is not rocket science. The manual sugar cane machine is cheaper and more suitable for people with muscle strength and some handy-person skills. However, assembling the machine is intuitive and will take only a few minutes for the right person, a nightmare for those who are not used to it. Moreover, a few manual cane sugar juicer users end up connecting the machine with the motor for easier operation.

However, if you can afford the electric machine, no doubt, buying it is the only way to make your sugar cane juice quick and easy.

I am from Hawaii looking to purchase a electric sugar cane juicer for our Sugar Cane Museum. I would like to have the cost of the machine and where in California would you be able to ship to. I understand that from California, I will have to make arrangement to ship to Hawaii.

Also, do you accept business checks — we are a non profit organization.

Please let me know.

Hi Evelyn,

I am sure, it is not a problem to negotiate the sugar cane delivery to the Hawaii. Few seller will happy to do it for you, not necessary form California. You just select the machine on amazon, for example, and contact the amazon seller to find out T&C of delivery. You have to select seller under the Add to Car and buy now buttons in the tight side and find the seller contacts under the return and refund menu option.

Alternatively, you can contact directly this sellers of these premium machines http://www.piojuicer.com or http://www.facebook.com/tubodelight

What is price of manual sugar cane juicer machine for home ”

Dear Dr. Alay Ahmad, The prices for manual Sugar Cane machines are ranging between $215–270 depending on retailer and season. If you click on the buy button, you can check the best prices available at the moment. Hope it helps.